ZIBO BOJI MACHINERY CO.,LTD

-

HOME

- COMPANY

- PRODUCTS

Centrifugal Pump

- Type:Pump

- Code:

-

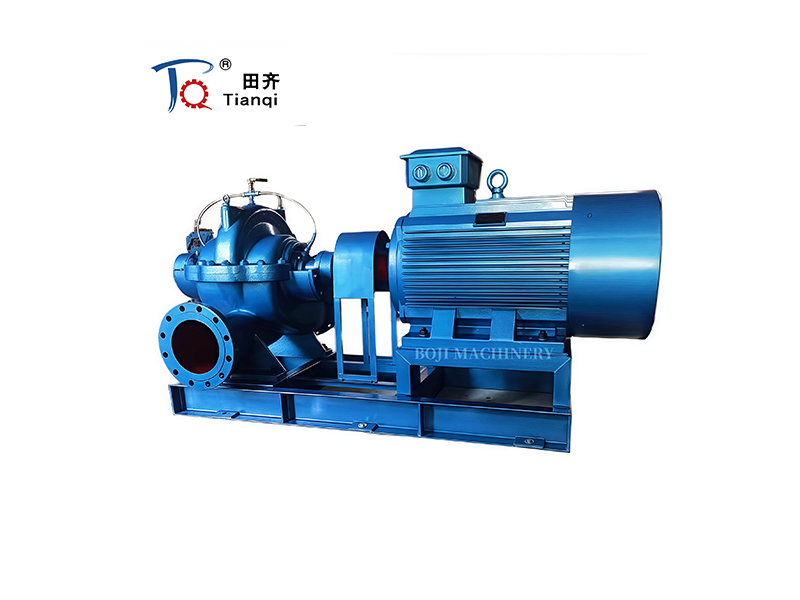

The split-case pump (split-case circulation), also known as the single-stage double-suction centrifugal pump, is mainly characterized by a large flow rate of the conveyed medium. The working principle of the split-case pump operation: The impeller is installed in the pump casing and fastened to the pump shaft, which is directly driven by the motor. There is a liquid suction pipe connected to the suction pipe in the center of the pump casing. The liquid enters the pump through the bottom valve and the suction pipe. The liquid discharge port on the pump casing is connected to the discharge pipe. When the rotational speed of the pump is constant, its head and flow rate are related to the diameter of the impeller.

- Product Description

The basic structure of a centrifugal pump consists of eight parts, namely: impeller, pump body, pump cover, water retaining ring, pump shaft, bearing, sealing ring, stuffing box, and axial force balancing device.

The impeller is the core component of a centrifugal pump, featuring high rotational speed and large output force.

2. The pump body, also known as the pump casing, is the main body of the water pump. It serves a supporting and fixing function and is connected to the bracket where the bearing is installed.

3. The function of the pump shaft is to connect the coupling with the motor and transfer the motor's torque to the impeller. Therefore, it is the main component for transmitting mechanical energy

4. The sealing ring is also known as the leakage reduction ring.

5. The stuffing box is mainly composed of packing, which prevents the water inside the pump from flowing out and also stops the outside air from entering the pump. Always maintain the vacuum inside the water pump! When the pump shaft rusts against the packing and generates heat, water needs to be injected into the water seal ring through the water seal pipe to cool the packing!

6. Axial force balancing device: During the operation of a centrifugal pump, as the liquid enters the impeller at low pressure and exits at high pressure, the pressure on both sides of the impeller is unequal, generating an axial thrust towards the inlet direction. This can cause axial movement of the rotor, leading to wear and vibration. Therefore, an axial thrust bearing should be installed to balance the axial force.

Previous:Multistage Water Pump

Zibo Boji Machinery Co., Ltd

CONTACTS-

Tel:+86 13011621901

-

WhatsApp:+86 13573378199

-

E-mail:manager@bojimachinery.com

-

Address:

Zibo Boji Machinery, Fangjiazhuang Industrial Park, Boshan District, Zibo of Shandong Province

WhatsApp Wechat

Wechat

Copyright @ 2025 Zibo Boji Machinery Co., Ltd. All Rights Reserved.

- COMPANY