ZIBO BOJI MACHINERY CO.,LTD

-

HOME

- COMPANY

- PRODUCTS

Application of reducers in the mining industry

2025-07-18

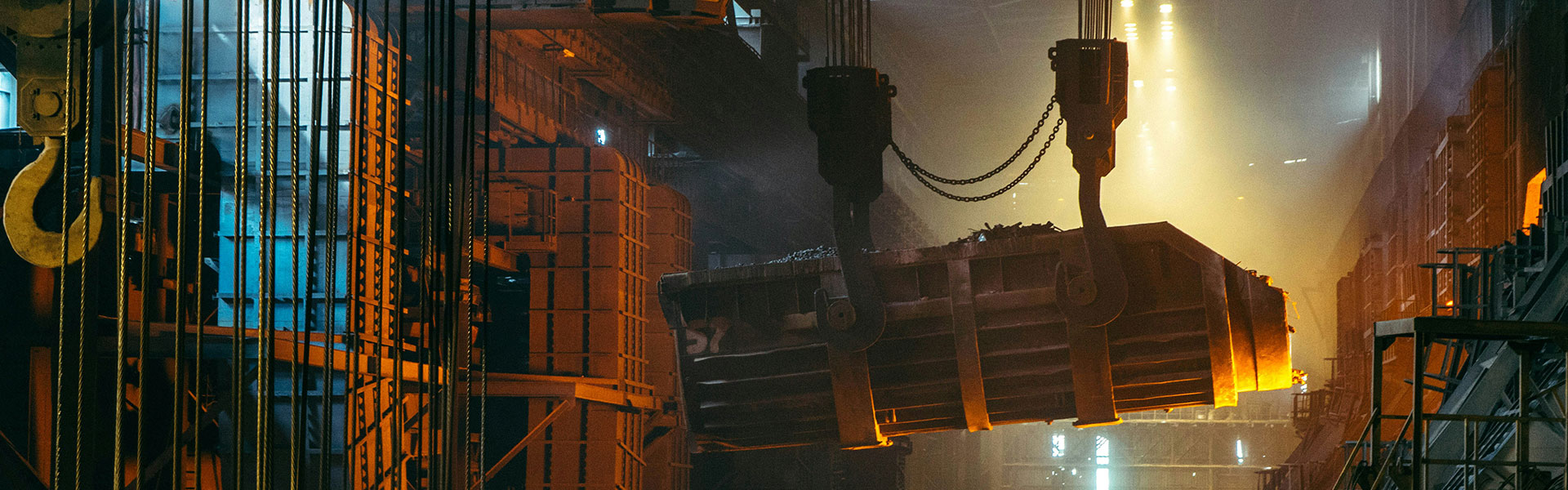

In the modern mining industry the core 'power' and 'endurance' of equipment directly determine production efficiency and operational safety. As an indispensable power transmission core in mining machinery, the reducer is providing crucial foundational support for the global mining industry to cope with extreme conditions, achieve cost reduction and efficiency improvement, and facilitate green transformation, thanks to its outstanding reliability, strong load-bearing capacity, and continuous innovative technology.

Excellent adaptability to extreme environments

The harsh environment of mining operations is arguably the harshest in the industry: heavy loads, shocks, high temperatures, high humidity, high dust, and continuous operation... From underground excavation, hoisting, and transportation, to surface crushing, grinding, screening, and mineral processing, every link poses a severe test to the ultimate performance of driving equipment.

Modern high-performance mine-specific reducers achieve torque multiplication and smooth power transmission through their super strong structural design, advanced materials science, and precision manufacturing processes, effectively resisting impact and vibration. Efficient heat dissipation design and multiple sealing technologies ensure the purity and effectiveness of internal lubrication in harsh environments, preventing leaks, greatly enhancing the average fault-free time of equipment, and reducing unplanned downtime, making them the 'power guardian' that ensures 24/7 continuous operation in mines.

A key link to improve efficiency and safety

In the process of mining modernization, production efficiency and personnel safety are core demands. High-performance gear reducers play a key role in this.

1. Improve equipment reliability:

In key equipment such as mine hoists, belt conveyors, ball mills, and rotary kilns, the stable operation of the reducer is directly related to the smoothness and safety of the entire production line, preventing production interruptions or even safety accidents caused by power failures.

2. Achieve efficient transmission:

The optimized gear design and high-precision processing have resulted in higher transmission efficiency, significantly reducing energy loss and saving considerable operating costs for energy-intensive mining companies.

3. Adapt to harsh working conditions:

The gearbox designed specifically for mines has a stronger overload capacity and shock resistance, allowing it to handle harsh conditions such as ore blockage and heavy load starting, thus protecting the drive motor and subsequent mechanical structure.

4. Collaborative control:

Seamlessly integrated with the automated control system to ensure precise power balance and synchronous control for systems that require multi-machine drive, such as long-distance conveyors and large grinding equipment, enhancing overall operational stability.

Practice green sustainable development

The development of the mining industry must be coordinated with environmental protection. Modern reducer technology actively contributes to the construction of green mines:

1.Energy saving and consumption reduction:

Higher transmission efficiency directly reduces electricity consumption and lowers carbon emissions.

2.Long lifespan design:

Excellent wear resistance and reliability extend the equipment's lifespan, reducing resource consumption and waste generation.

3.Environmental lubrication:

Compatible with high-performance environmental lubricants, and prevents leakage through good sealing, protecting the soil and water systems in the mining area.

Looking to the future

In the future, as mining technology advances towards deeper, smarter, and greener directions, gear reducer technology will also continue to evolve, moving towards greater power density, higher intelligence levels, longer service life, and digital management throughout the entire lifecycle. TianQi will deepen its collaboration with mining companies, providing a complete set of solutions from products to health management services, jointly creating a new future for safe, efficient, and green mining.

Zibo Boji Machinery Co., Ltd

CONTACTS-

Tel:+86 13011621901

-

WhatsApp:+86 13573378199

-

E-mail:manager@bojimachinery.com

-

Address:

Zibo Boji Machinery, Fangjiazhuang Industrial Park, Boshan District, Zibo of Shandong Province

WhatsApp Wechat

Wechat

Copyright @ 2025 Zibo Boji Machinery Co., Ltd. All Rights Reserved.

- COMPANY