ZIBO BOJI MACHINERY CO.,LTD

-

HOME

- COMPANY

- PRODUCTS

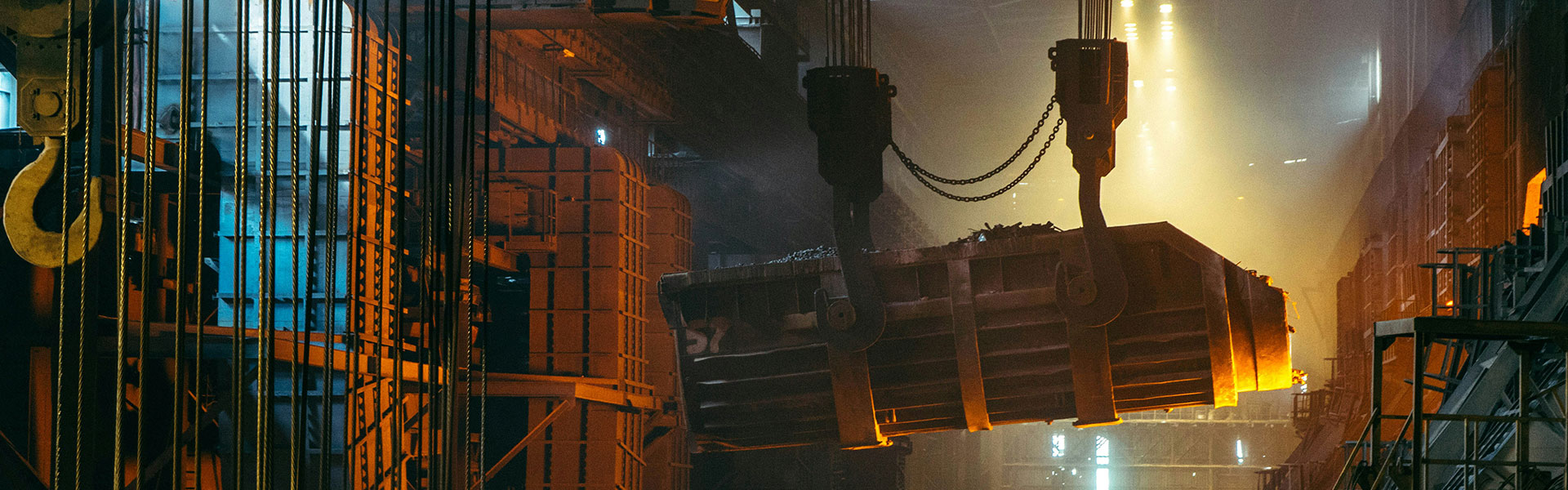

Application of reducers in lifting machinery

2025-07-18 The reducer is the most critical transmission component in lifting machinery, and its performance directly determines the crane's lifting capacity, operational smoothness, safety and reliability, and work efficiency. It can be said that without a high-performance reducer, there is no modern efficient lifting machinery.

The reducer is the most critical transmission component in lifting machinery, and its performance directly determines the crane's lifting capacity, operational smoothness, safety and reliability, and work efficiency. It can be said that without a high-performance reducer, there is no modern efficient lifting machinery.The main role of the reducer in lifting machinery

1. Deceleration and increasing torque:

The drive motor of a crane typically uses a high-speed, low-torque three-phase asynchronous motor to meet size and cost requirements. However, lifting operations require low speed and high torque to hoist heavy loads. The reducer uses gear transmission to reduce the motor's high speed to the low speed required by the drum or wheel, while amplifying the motor's low output torque several times or even tens of times, thereby generating enough force to lift heavy objects.

2.Matching inertia:

The rotor inertia of the motor is relatively small, while the inertia of the load is very large. Through the reduction effect of the reducer, the inertia of the load can be converted to the motor shaft, reducing it to match the inertia of the motor rotor. This greatly improves the dynamic response characteristics of the system, making the starting and stopping processes smoother and more controllable, avoiding slipping or impact.

3. Load transmission:

The gearbox housing is usually made of high-strength cast steel and serves as an important support structure connecting the motor, drum, wheels, and frame. Its structural design is intended to withstand the enormous reactive forces, torque, and radial loads generated during the lifting process.

4.Brake Integration:

In the lifting mechanism of the crane, the brake is often directly installed on the high-speed shaft of the reducer. The compact design of the reducer allows the brake to act quickly and effectively on the transmission system, ensuring safety.

Common types of gear reducers used in lifting machinery

Depending on the different types and mechanisms of cranes, different structures of gear reducers will be selected.

1. Lifting mechanism:

The medium-hard tooth surface reducer for QJ type cranes is the most classic and commonly used reducer for lifting and running mechanisms of cranes. It features a three-stage transmission, horizontally split housing, high strength, and large load capacity.

The three-point reducer for QS type cranes has a flanged end on one side of the housing, which can be directly mounted onto the drum with bolts, while the other end is supported by a base, forming a "three-point" structure. This compact design effectively reduces the support span of the drum and is widely used in the lifting mechanisms of bridge and gantry cranes.

Planetary gear reducers, especially drum planetary gear reducers. It integrates the planetary gear reducer directly inside the drum, making the structure extremely compact, lightweight, and with high torque density. It is increasingly used in modern large, efficient cranes.

2. Operating agency:

"Three-in-one" drive devices are the mainstream configuration of modern crane operating mechanisms. It integrates the motor, brake, and reducer into a compact housing. Its advantages include a compact structure, ease of installation, maintenance-free operation, and an aesthetically pleasing appearance. Common types include bevel gear reducers and worm gear reducers.

3. Rotary mechanism:

Used for the upper rotating platform of tower cranes, truck cranes, etc. Among them, the planetary gear reducer is the preferred choice for the rotating mechanism due to its small size, high transmission ratio, and high load capacity, and is usually installed in a vertical position; the cycloidal pinwheel reducer is also widely used, featuring a large transmission ratio and compact structure.

4. Amplitude mechanism:

Used to change the elevation angle or amplitude of the crane boom. Depending on the drive type, a worm gear reducer or a hard-tooth gear reducer may be used.

Special requirements for the reducer

Due to the special nature of crane operations, there are much higher requirements for its reducer than for general equipment.

1. High reliability:

It is essential to ensure absolute reliability under long periods, heavy loads, and intermittent work; failure may lead to serious accidents.

2. High load capacity:

Gears, bearings, and casings must be able to withstand huge impact loads and fatigue loads.

3. High security:

Usually works in coordination with the braking system to ensure that it can safely support the load in the event of a power outage or failure.

4. High Efficiency:

High efficiency means less energy loss and less heat generation, which is especially important in work modes that involve frequent starts and stops.

5. Good sealing performance:

Cranes often operate in dusty, humid, or even outdoor environments. Good sealing can prevent lubricant leakage and the intrusion of impurities, thereby extending their lifespan.

6. Low noise:

Especially for cranes operating in urban or indoor environments, low noise operation is an important indicator.

Summary

The reducer plays a dual role as a "power amplifier" and "rhythm controller" in lifting machinery. It transforms the "small" power of the motor into a tremendous force capable of shaking thousands of pounds, while ensuring that the entire motion process is smooth, precise, and safe. China TianQi is committed to technological innovations in hard-toothed reducers, grinding processes, planetary transmissions, integrated design, and other aspects, promoting the development of lifting machinery towards greater tonnage, higher efficiency, and smarter solutions.

Zibo Boji Machinery Co., Ltd

CONTACTS-

Tel:+86 13011621901

-

WhatsApp:+86 13573378199

-

E-mail:manager@bojimachinery.com

-

Address:

Zibo Boji Machinery, Fangjiazhuang Industrial Park, Boshan District, Zibo of Shandong Province

WhatsApp Wechat

Wechat

Copyright @ 2025 Zibo Boji Machinery Co., Ltd. All Rights Reserved.

- COMPANY