ZIBO BOJI MACHINERY CO.,LTD

-

HOME

- COMPANY

- PRODUCTS

Global transportation system upgrade: Technological innovation of reducers drives efficient logistics transformation

2025-07-15

Under the global logistics automation and Industry 4.0 trend, reducers, as the core transmission components of the conveying system, are experiencing a new round of technological iteration and market expansion. From port container transportation to intelligent factory production lines, efficient and reliable reducers are becoming the key to enhancing logistics efficiency.

1.Global market demand continues to grow

With the rapid development of e-commerce and cross-border trade, the global market size of conveying equipment is expected to exceed 20 billion US dollars by 2025. The Asia-Pacific region has become the growth engine, with intelligent warehousing and port automation projects in countries like China and India accelerating their implementation, driving the demand for high-performance reducers. Europe has seen an increase in demand for energy-efficient reducers due to the return of manufacturing and green logistics policies.

2.Technological innovation enhances transportation efficiency

The traditional transportation system is transitioning from "coarse transmission" to "precise control". Enterprises such as SEW from Germany and Sumitomo from Japan have launched servo reducers combined with frequency conversion technology. These reducers can adjust the speed of the conveyor belt to the millimeter level, significantly reducing energy consumption. Moreover, the modular design of worm gear reducers is widely used in industries with strict hygiene requirements such as food and medicine. Their sealing and corrosion resistance meet the demanding environmental needs.

3.Integration of Intelligence and Automation

In intelligent warehouses like those of Amazon and JD, the combination of reducers with the Internet of Things (IoT) and AI algorithms has become a new trend. Through vibration sensors and temperature monitoring modules, reducers can provide real-time feedback on their operating status, preventing unexpected shutdowns. The latest "intelligent reducer" launched by Bosch Rexroth in Germany can even autonomously adjust torque to adapt to different weights of goods, increasing sorting efficiency by up to 30%.

4.Challenges and Future Directions

Despite the promising prospects, fluctuations in raw material costs and the reconfiguration of global supply chains still pose challenges. The industry is reducing costs and increasing efficiency through innovations such as 3D-printed gearboxes and lightweight composite materials. In the future, as the expansion of industries like new energy lithium batteries and photovoltaics continues, high-temperature-resistant and dust-proof reducers will become new growth points.From traditional manufacturing to modern intelligent logistics, the technological evolution of reducers is profoundly reshaping the global transportation system landscape. Under the dual goals of efficiency and sustainability, this core component will continue to drive the upgrading wave of the logistics industry.

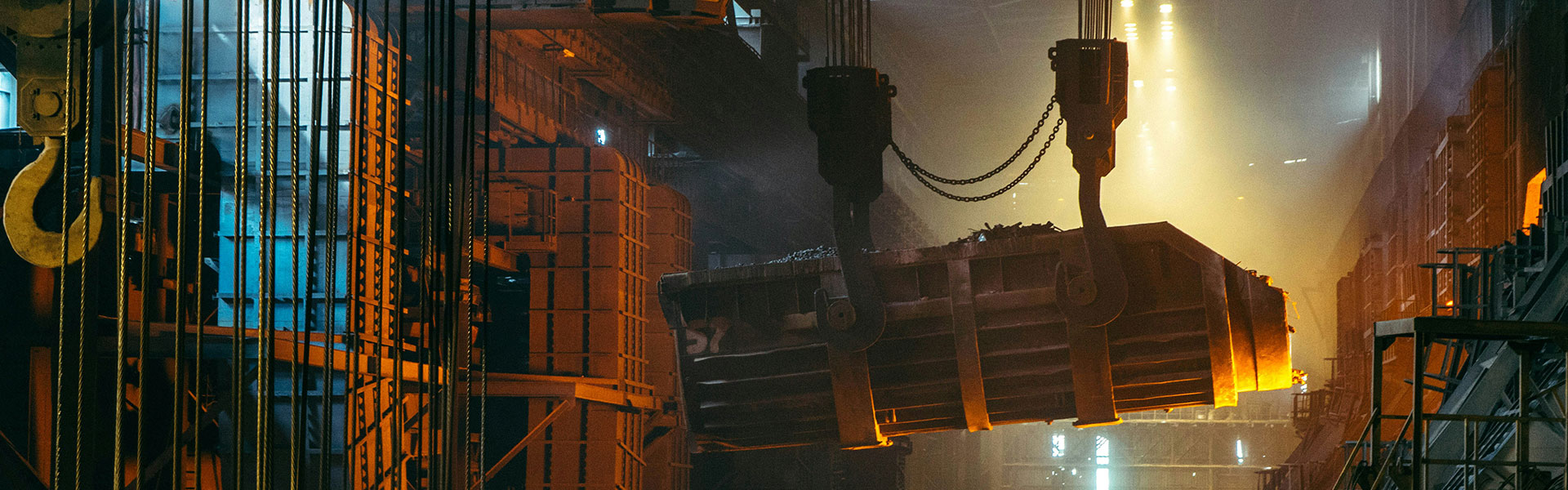

- Previous:Application of Reducers in the Metallurgical Industry ——High-performance reducers help the metallurgical industry move towards a new era of intelligence and greenness

- Next:The application of reducers in the global wastewater treatment industry: The "stabilizer" in the water purification chain

Zibo Boji Machinery Co., Ltd

CONTACTS-

Tel:+86 13011621901

-

WhatsApp:+86 13573378199

-

E-mail:manager@bojimachinery.com

-

Address:

Zibo Boji Machinery, Fangjiazhuang Industrial Park, Boshan District, Zibo of Shandong Province

WhatsApp Wechat

Wechat

Copyright @ 2025 Zibo Boji Machinery Co., Ltd. All Rights Reserved.

- COMPANY